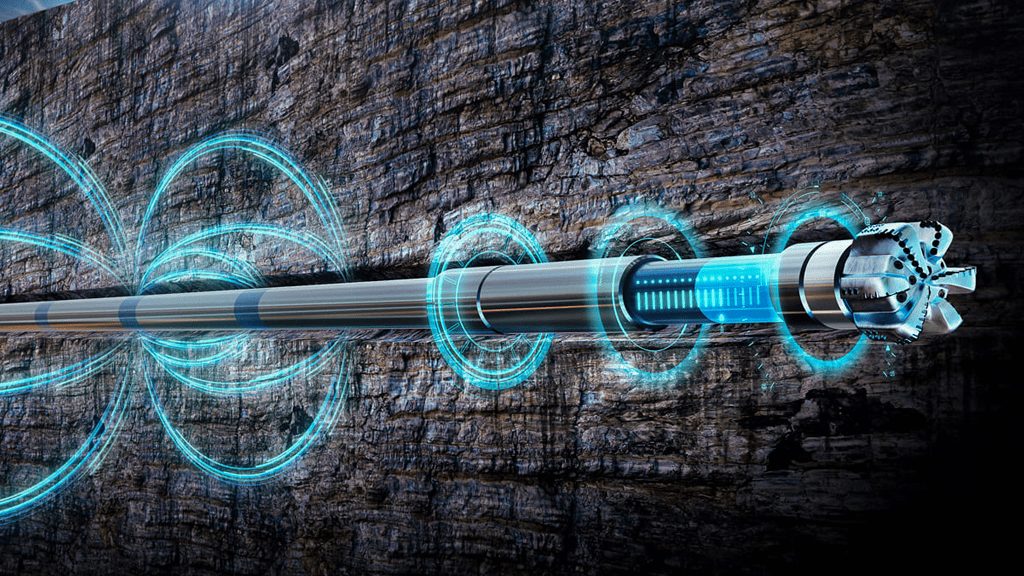

Unlock the potential of your drilling operations with tde powerline.

By converting standard drill pipes into intelligent digital conduits, tde powerline delivers real-time data transmission and continuous power supply directly to your drill site, ensuring enhanced decision-making and operational precision.

tde powerline elevates drilling efficiency with advanced power and seamless integration

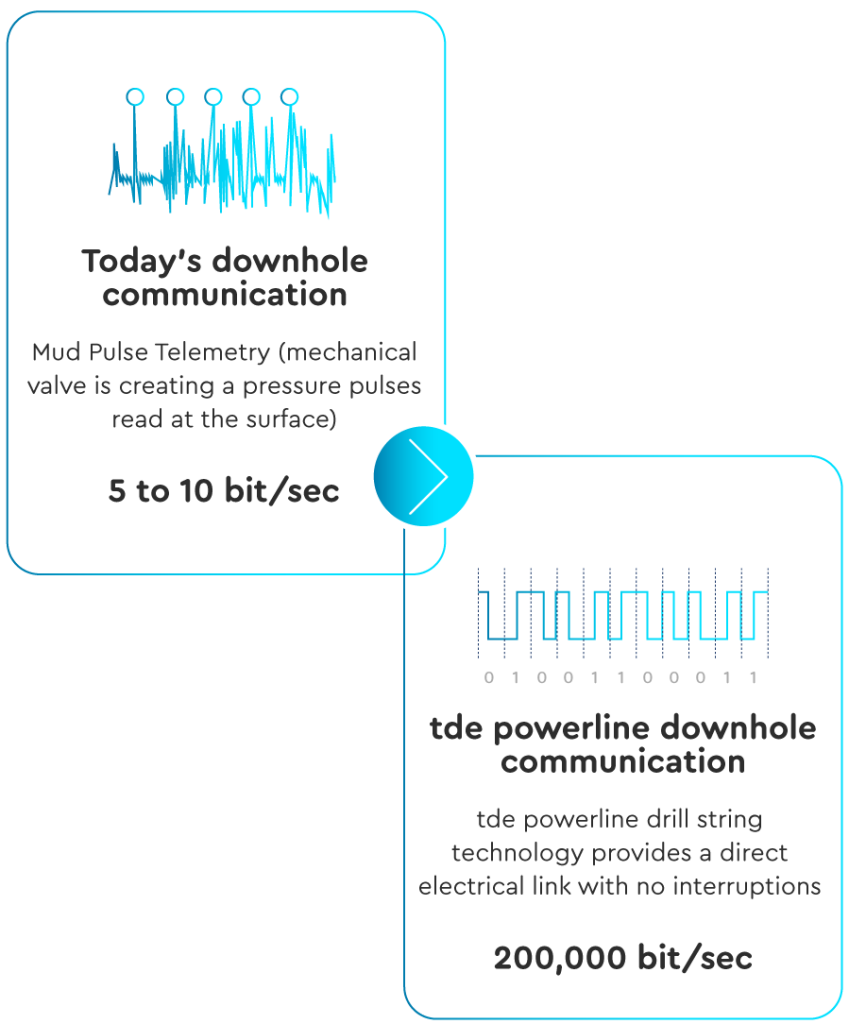

High downhole power and a remarkable data transfer rate enhance operational responsiveness.

Retrofit compatibility with existing drill pipes simplifies upgrades.

Absence of turbines and batteries promotes cleaner, more efficient operations.

The sustainable solution

To make pipes intelligent – upgrade existing drill pipes to digital capability and install onsite.

Our retrofitted design used with existing drill pipes means that no additional steel pipe manufacturing is needed, reducing CO2 emissions (1.85 tonnes of carbon per 1 tonne of steel).

Enhance drilling precision

With real-time downhole data and continuous power to reduce risk and costs by lowering the Non-Productive Time (NPT) and Invisible Lost Time (ILT) of drilling operations.

tde powerline advantages:

Low cost of ownership, operatorship and vendor-neutrality viable solution for all well programs and drilling applications

Game-changing data with continuous power reduce NPT/ILT, risk and cost

Enable next-step in automation and real-time engineering powering electro-mechanically activated downhole tools

tde powerline asm

tde powerline asm are along-string measurement and control devices installed in the drill string at multiple locations. tde powerline asm provides key measurements for monitoring the drill string, hole quality and drilling fluid properties.

tde powerline interface

tde powerline interface are devices to link tde powerline with third party downhole tools from service companies.

tde powerline is an open system, we invite third party M/LWD providers to enable their tools to utilize our tde powerline power and data highway.