Maersk Drilling continue to improve performance

Objectives

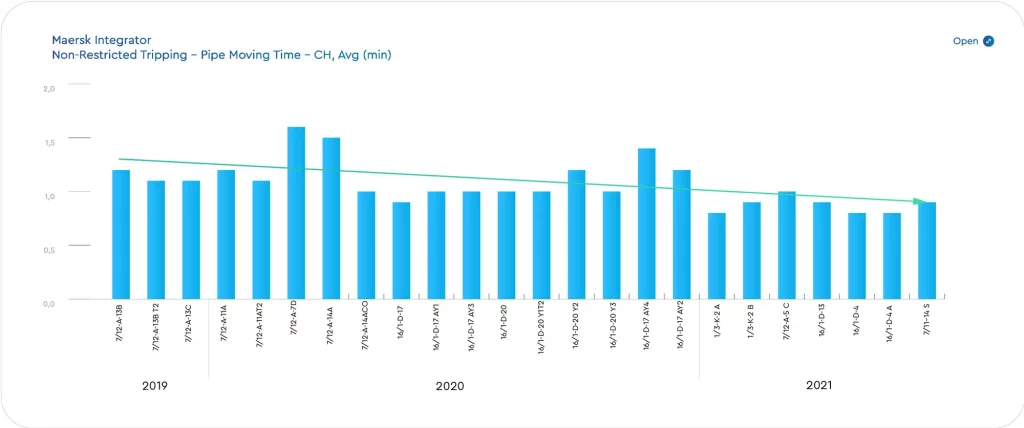

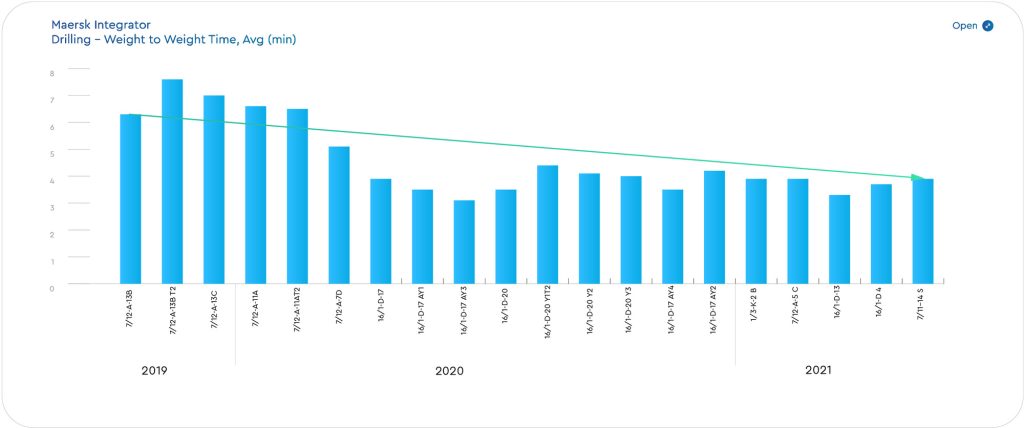

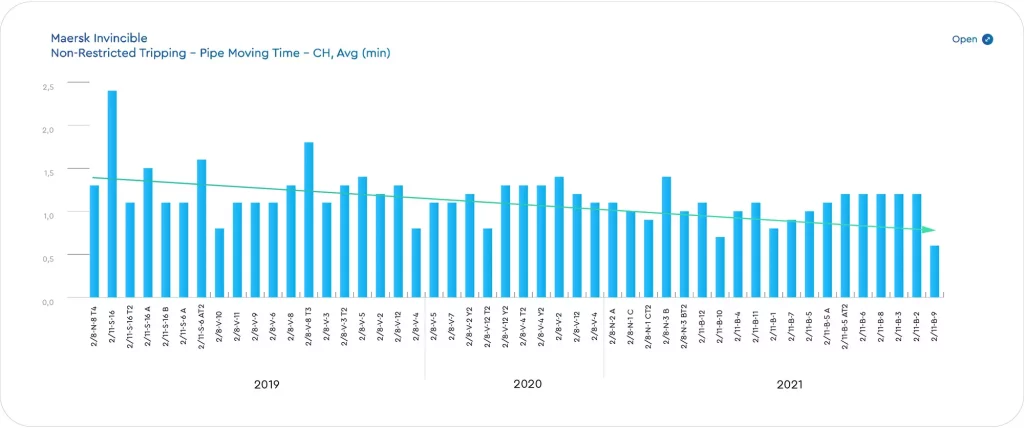

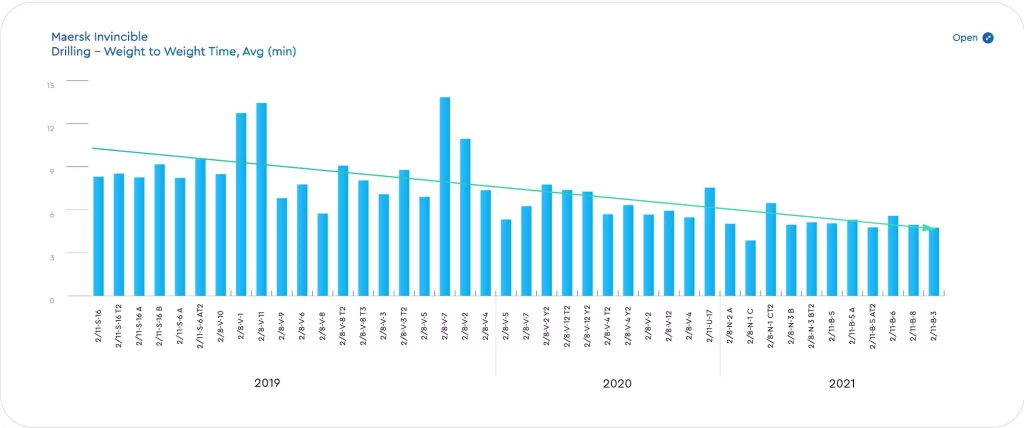

In 2019 Aker BP started using tde pronova with the objective of monitoring their operational performance of the rigs Maersk Invincible and Maersk Integrator that would result in a cost and carbon reduction of the well construction process. Focus was given to the specific KPIs Drilling – Weight to Weight time, non-restricted Casing – Slip to Slip connection time and non-restricted tripping – pipe moving time.

How pronova helps

tde pronova has been used as a key tool to detect and reduce inefficiencies for their drilling operations. Based on the continuous monitoring of a dedicated set of KPIs, the effort was made to reduce the performance gap between the actual performance and the targets set for each KPI. This resulted in an evident improvement of operational performance.

Results

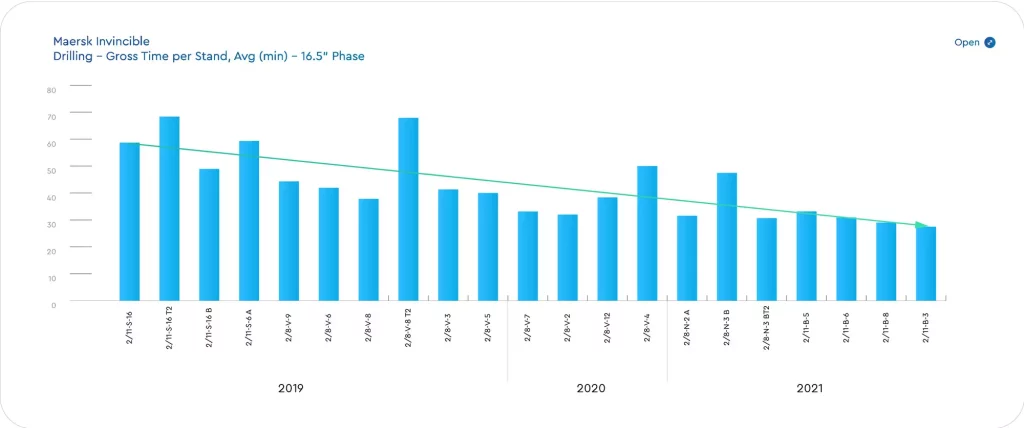

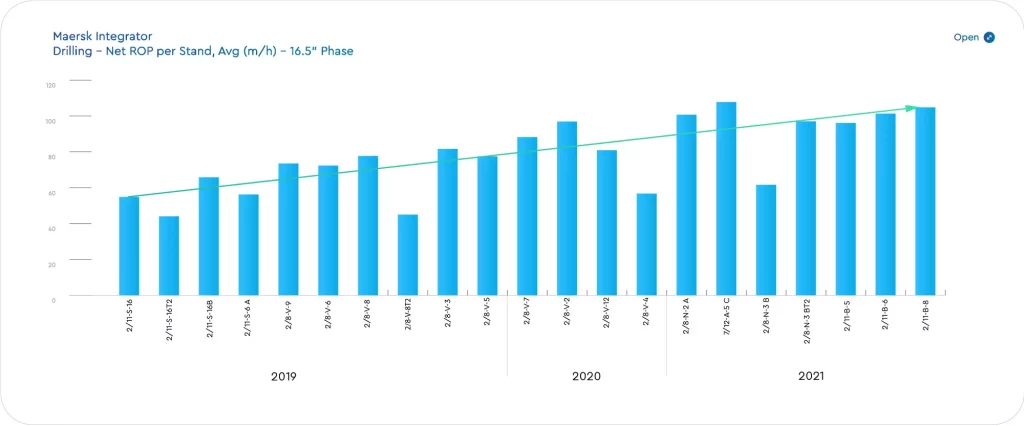

On both rigs, drilling crews made improvements on Drilling Weight to Weight Connection time, Pipe Moving Time, and Net ROP.

In addition to this, a significant reduction in Casing Slip to Slip Connection Time was achieved over the last two years onboard Maersk Invincible.

| Key Performance Indicators | Maersk Integrator | Maersk Invincible | ||

|---|---|---|---|---|

| Actual Savings (d) | Equivalent CO2 [metric t] | Actual Savings (d) | Equivalent CO2 [metric t] | |

| Non-Restricted Tripping – Pipe Moving Time – CH | 1.84 | 92.45 | 0.83 | 44.07 |

| Drilling – Weight to Weight Time | 4.34 | 217.06 | 4.63 | 246.08 |

| Non-Restricted Casing – Slip to Slip Connection Time | 0.63 | 31.65 | 0.92 | 49.11 |

| Total: | 6.79 | 341.16 | 6.39 | 339.26 |

In the case of Maersk Invincible, special emphasis was put on the 16.5” phase, where the Gross time per stand while drilling was drastically reduced.