Saving OMV $3m+ with tde pronova

Challenges

OMV started an infill drilling project known as MACI (Māui A Crestal Infill) in New Zealand in October 2020. Offshore drilling operations are performed on the Māui A platform by a modular platform rig the Archer Emerald. To reach technical excellence, proNova is used to measure and understand their operational performance and to identify areas for potential gains in consistency and efficiency. 5 wells were monitored and several KPIs were used for analysis, and benchmark targets were established and updated based on the rig performance.

How tde pronova helps

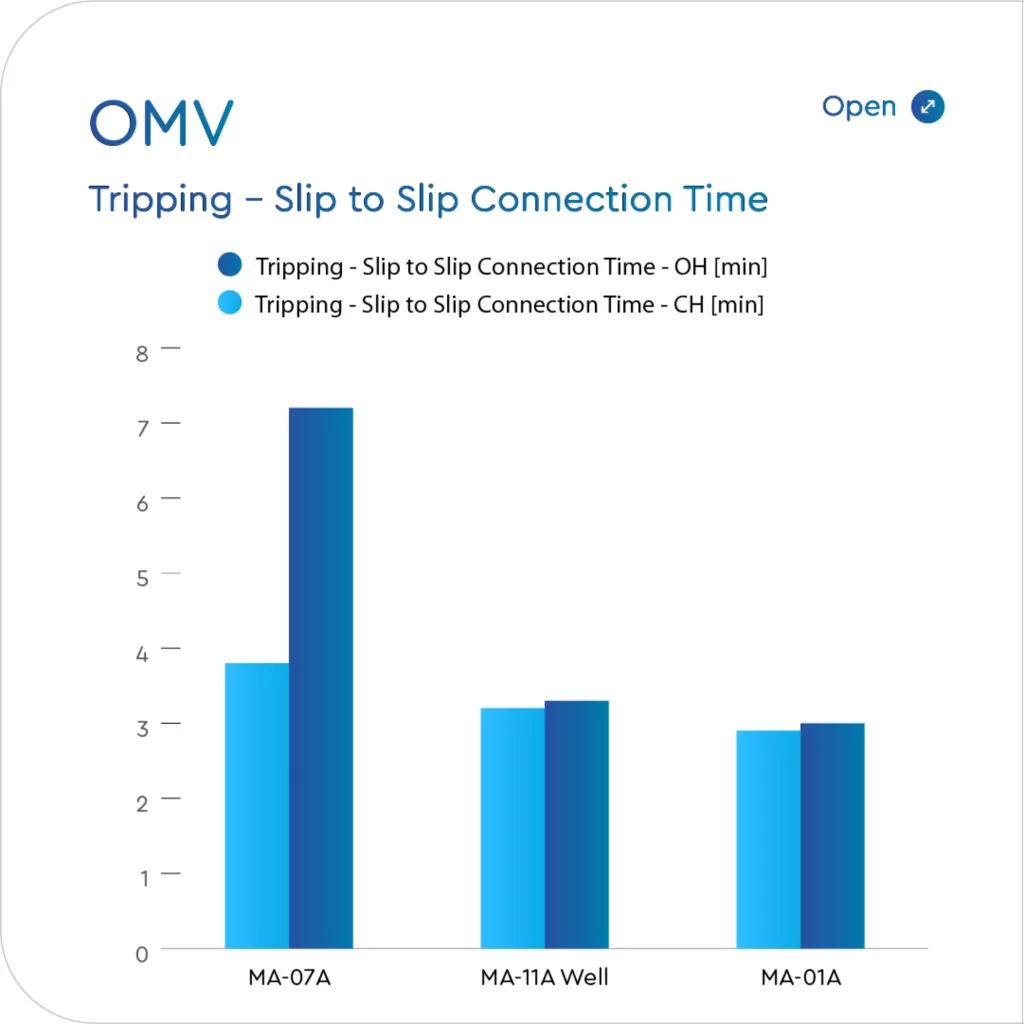

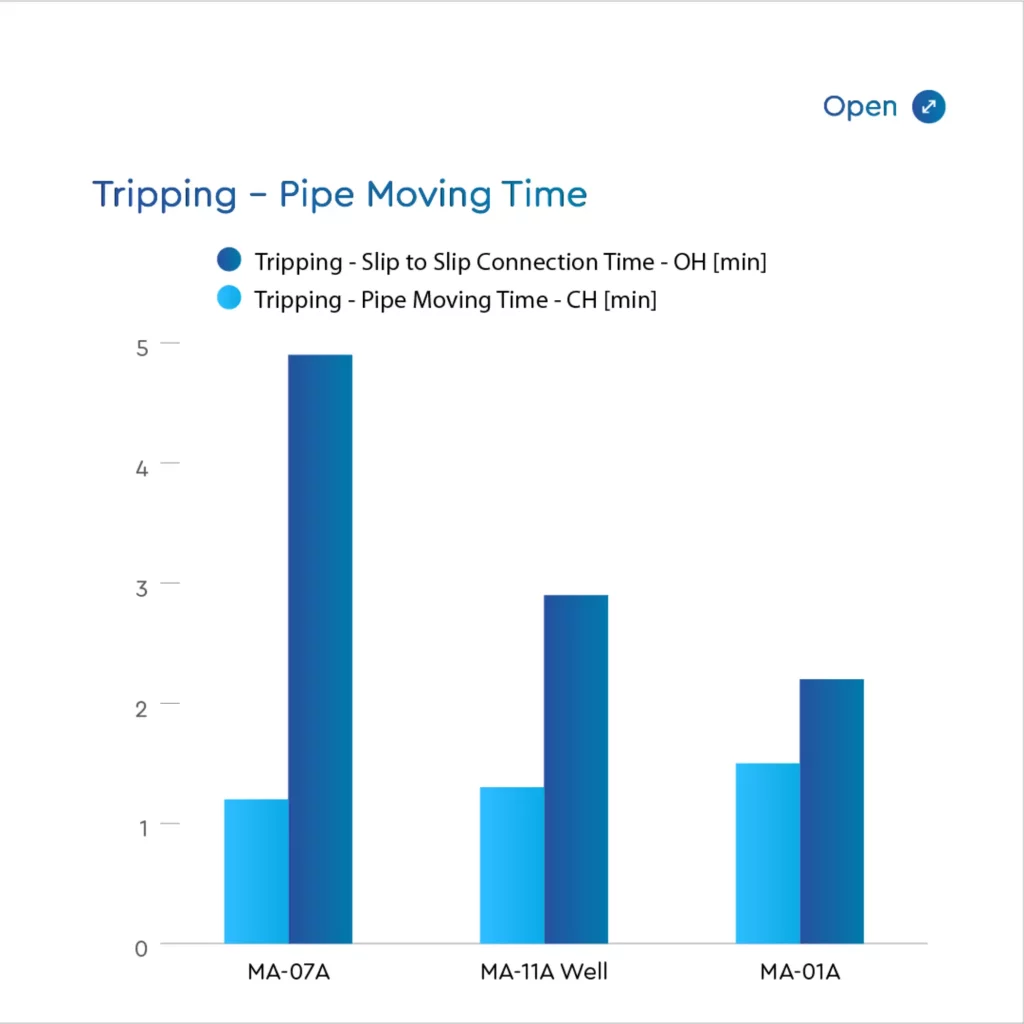

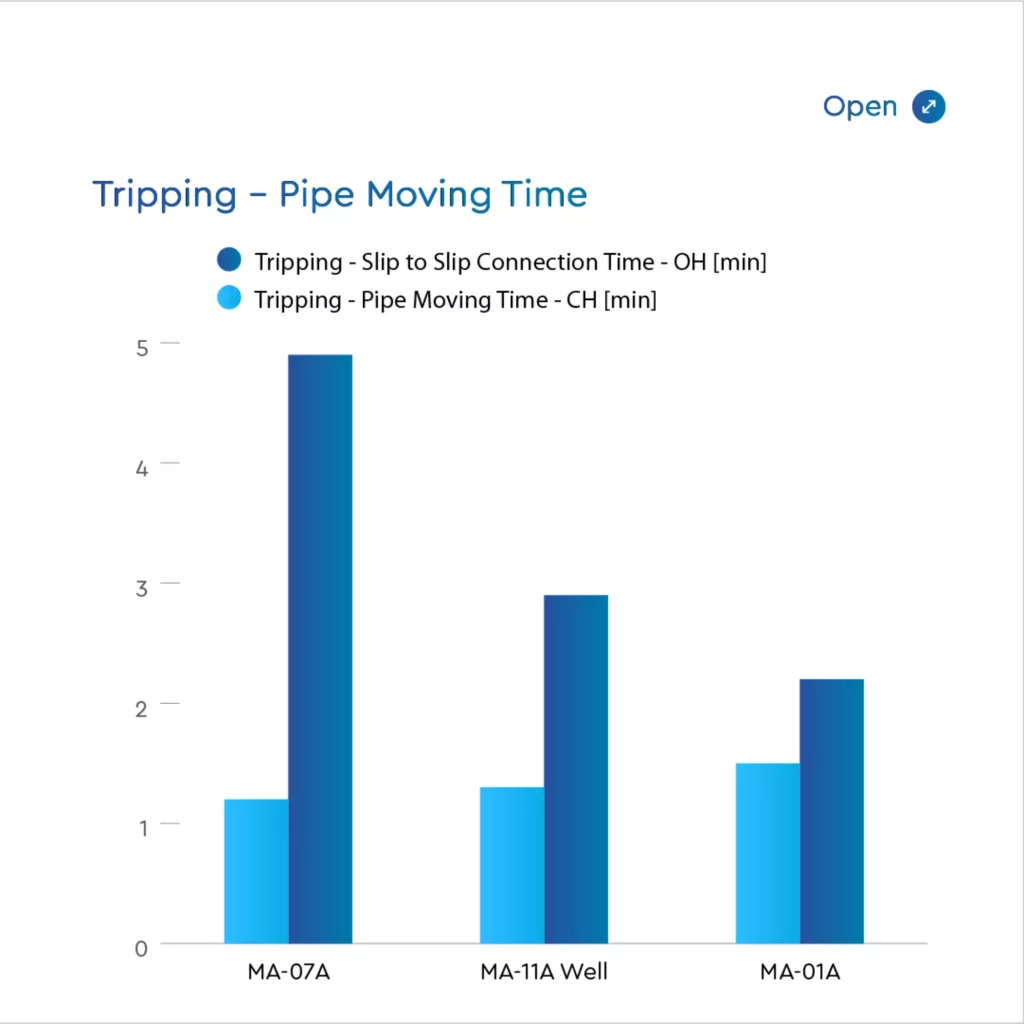

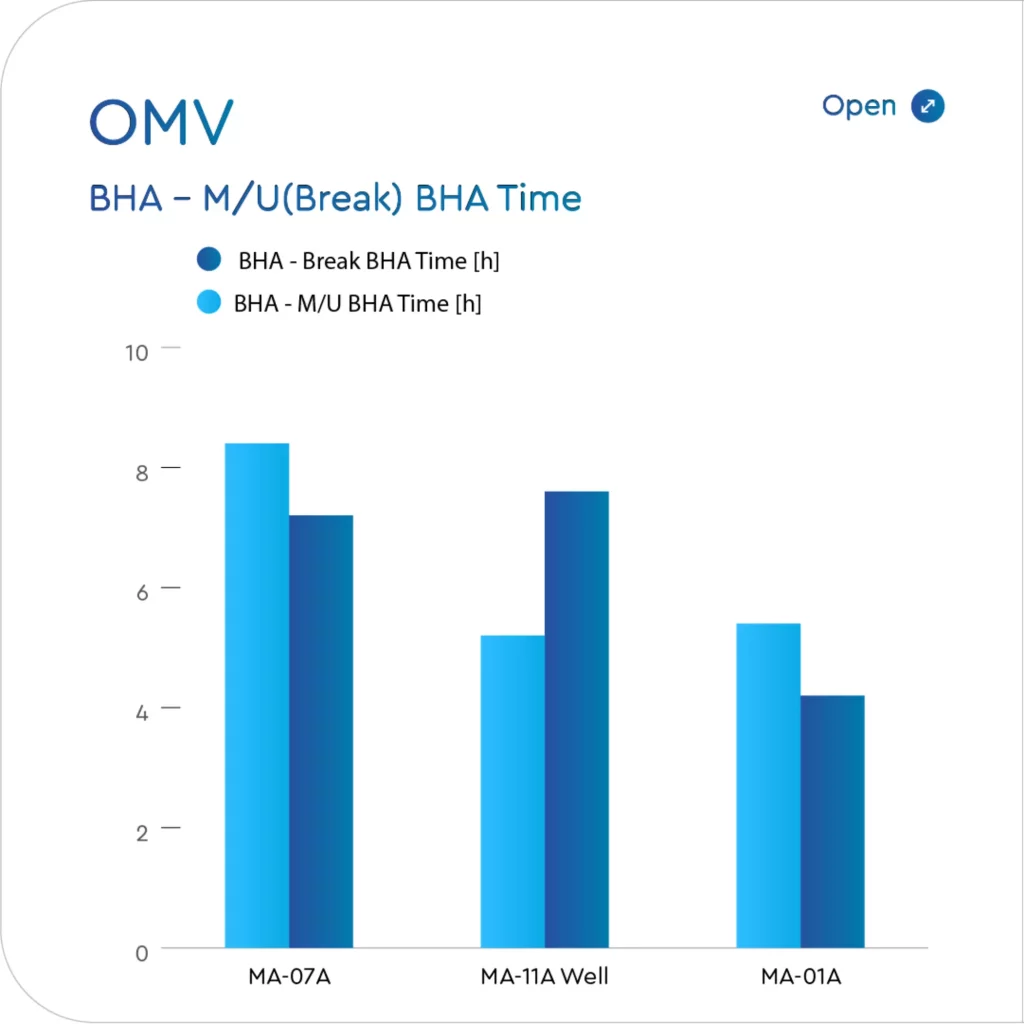

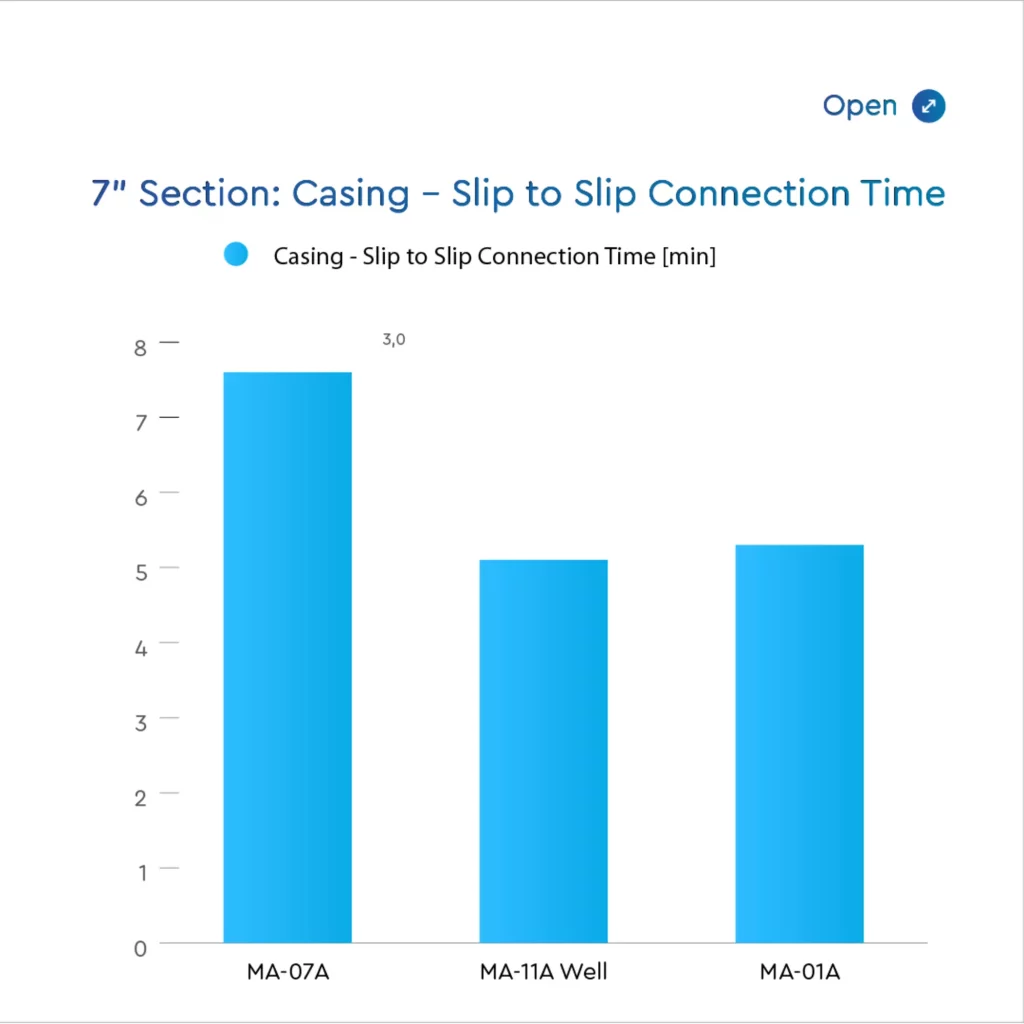

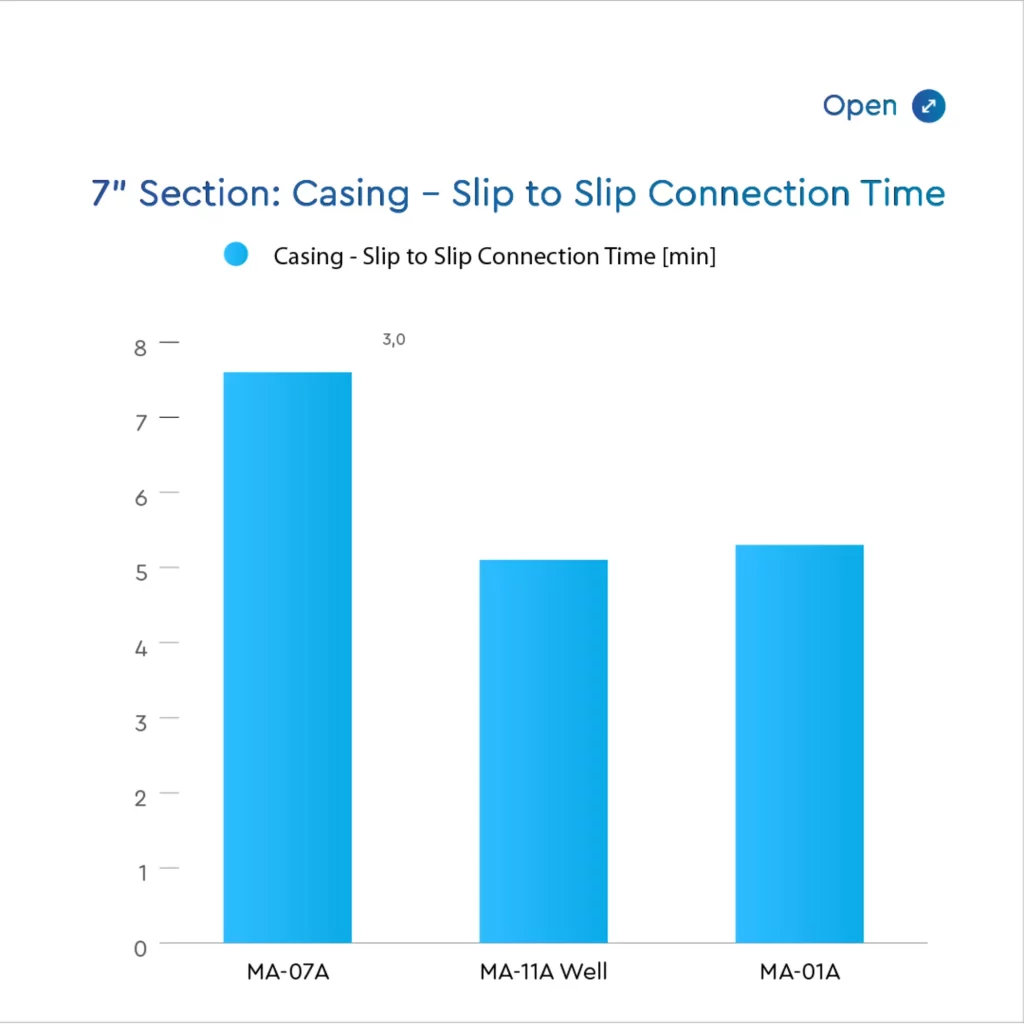

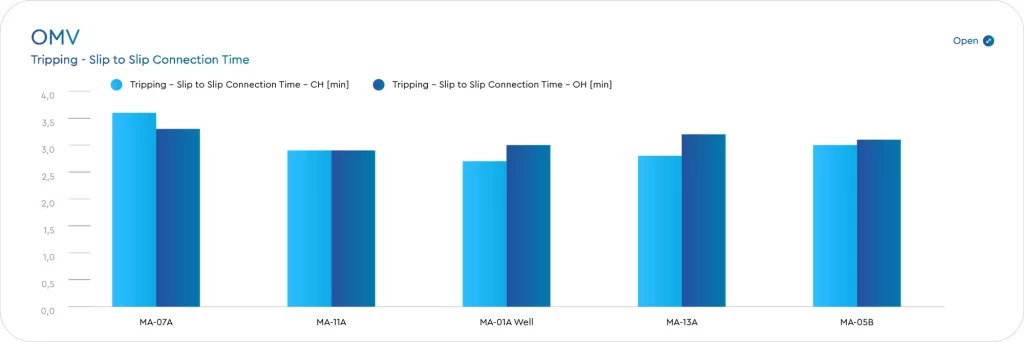

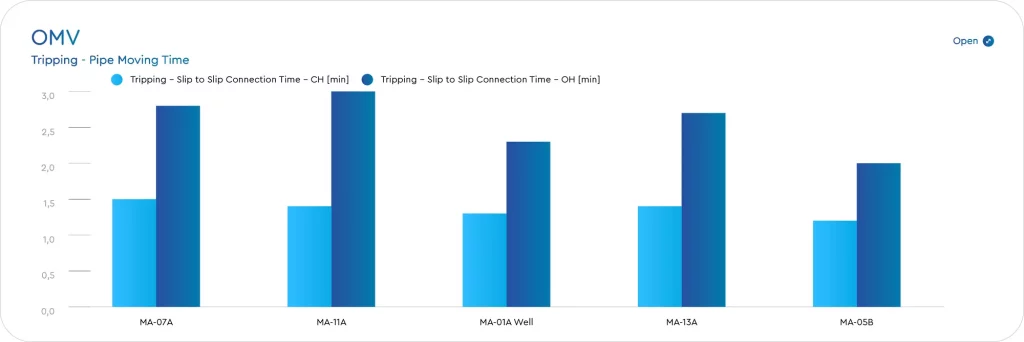

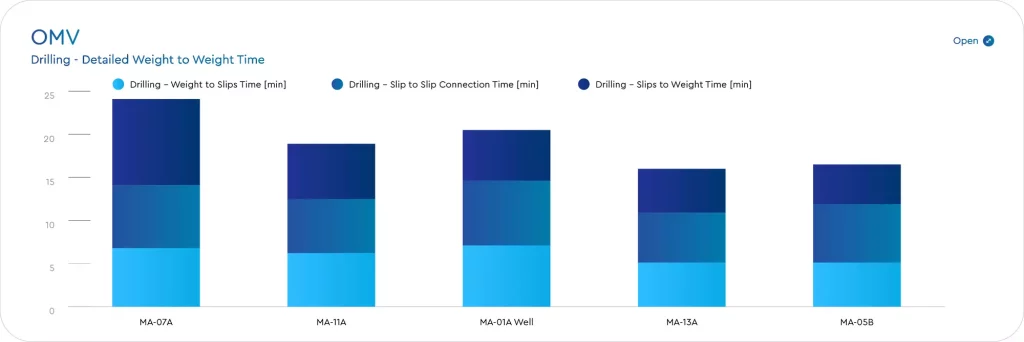

tde pronova was able to show the OMV NZ team how to identify inefficiencies in near real-time which resulted in rapid improvement of the performance. This was achieved by observing the differences between target benchmark and actual performance. Significant importance was assigned on controlling the components of Weight-to-Weight connection times, including Weight to Slips Time, Slip to Slip Time and Slip to Weight Time. In addition to Drilling KPIs, the focus was on Tripping and Casing KPIs. Based on the global best practice, successful drilling optimization is positioned with continuous improvement and consistency over an extended period, therefore OMV NZ were able to gain considerable time savings.

From the following results, it can be seen that:

| Key Performance Indicators | Actual Savings [d] |

|---|---|

| Tripping – Slip to Slip Connection Time – CH | 3.44 |

| Tripping – Slip to Slip Connection Time – OH | 1.42 |

| Tripping – Pipe Moving Time – CH | 1.54 |

| Tripping – Pipe Moving Time – OH | 0.72 |

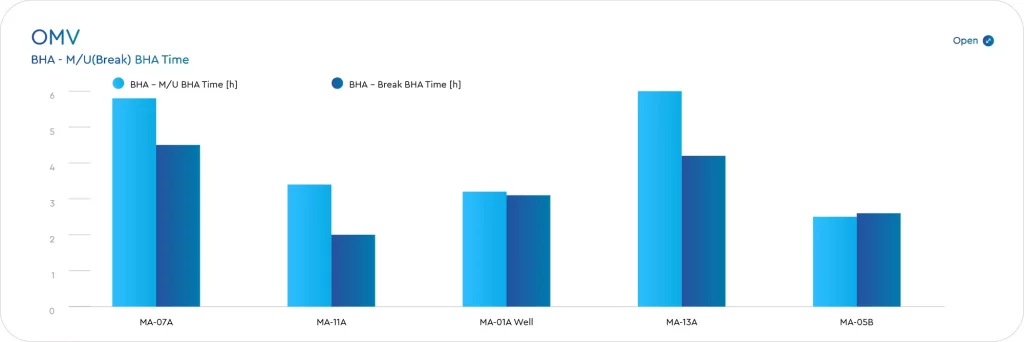

| BHA – M/U BHA Time | 2.47 |

| BHA – Break BHA Time | 1.42 |

| Drilling – Weight to Weight Time | 2.15 |

| Casing – Slip to Slip Connection Time | 1.00 |

| Casing – Pipe Moving Time – CH | 0.11 |

| Casing – Pipe Moving Time – OH | 0.14 |

| Summation of Actual Savings | 14.41 |