tde empowering Neptune Energy to save $5m

Challenges

In November 2019, Neptune Energy started a contract with the Deepsea Yantai semi-submersible rig, with a particular focus on performance on the Norwegian Continental Shelf. Offshore drilling operations have been monitored using tde proNova to understand and improve their operational performance. During this period, Deepsea Yantai has been conducting operations in three different fields – Duva, Gjøa and made one major discovery in 2020 in the Dugong field. During this time, 15 wells and their sidetracks have been monitored, and several KPIs were used for analysis. Benchmark targets were set and updated based on rig performance.

How tde pronova helps

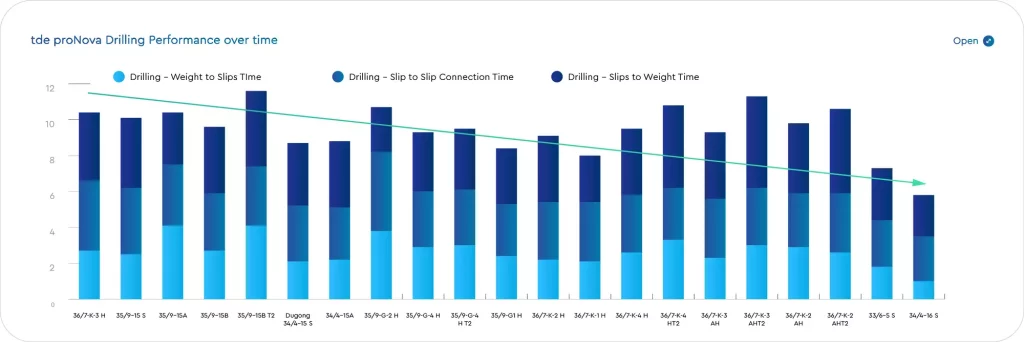

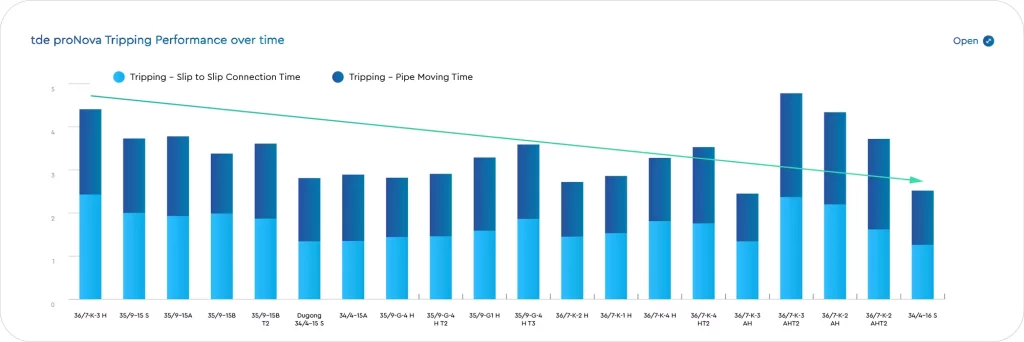

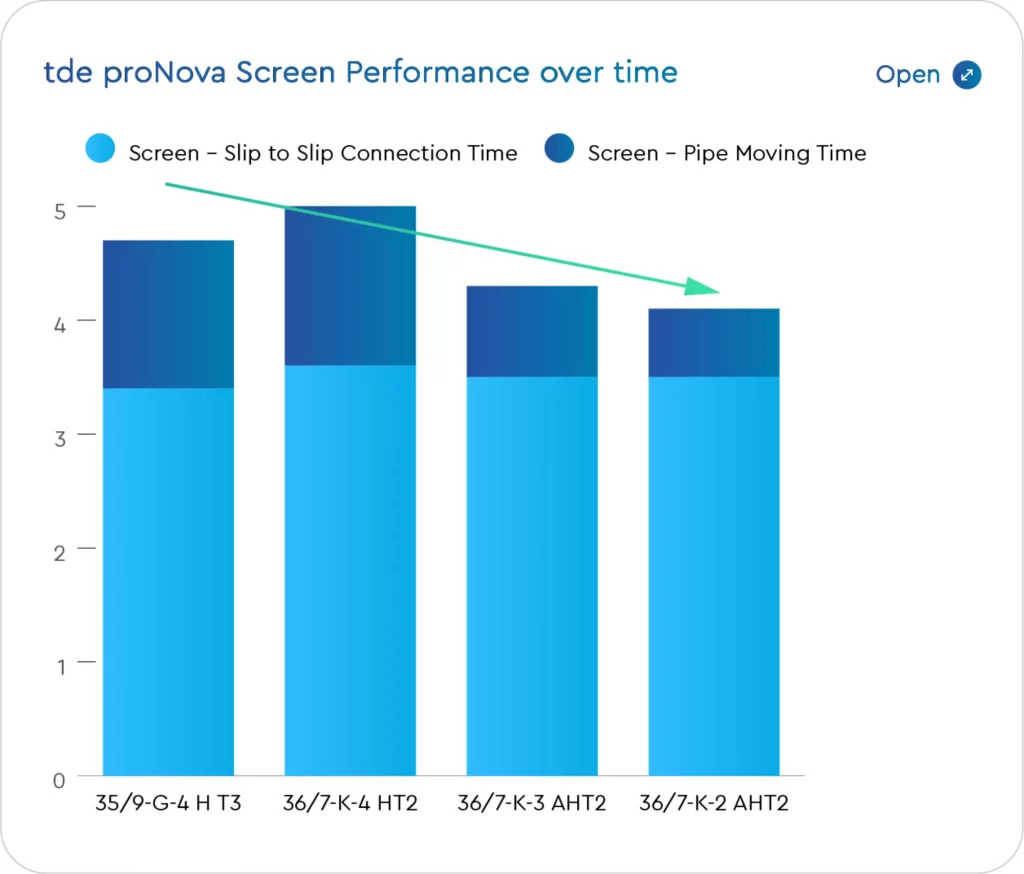

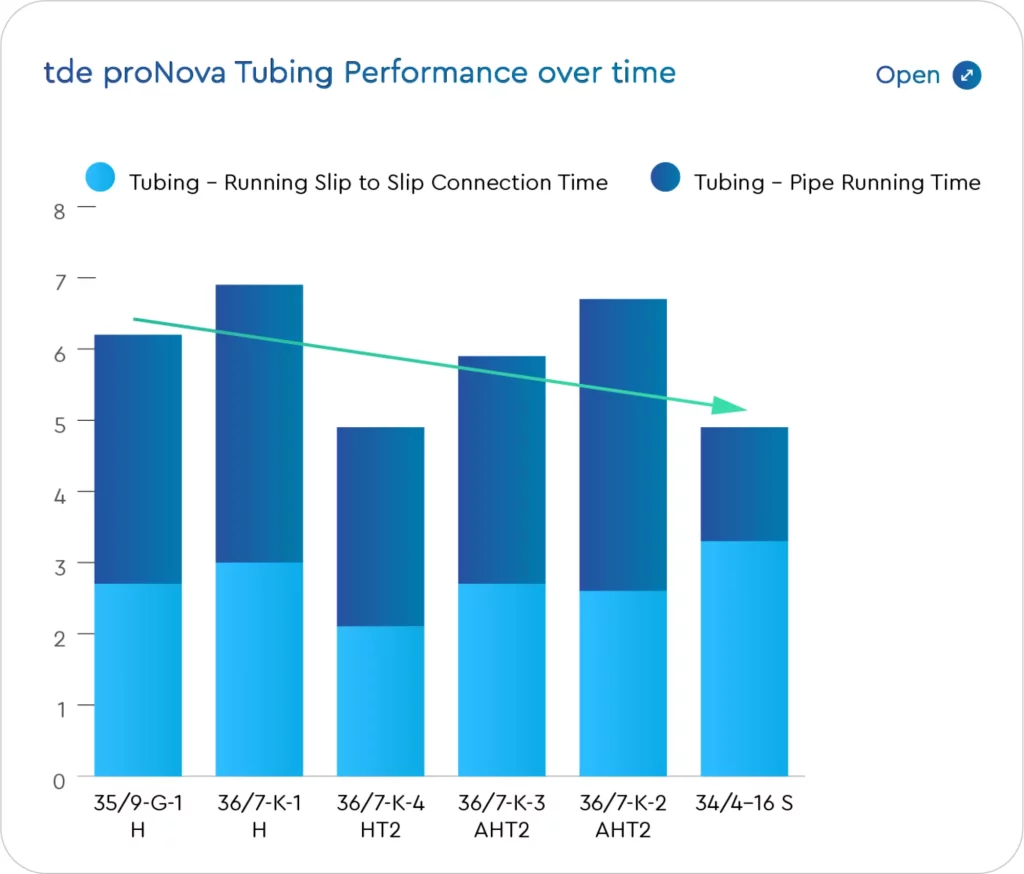

By observing the differences between target benchmark and actual performance, tde proNova was able to show Neptune Energy how to identify inefficiencies in near real-time, which resulted in a quick improvement of the performance. Importance was placed on controlling the components of Weight-to-Weight connection times, including Weight to Slips Time, Slip to Slip Time, and Slip to Weight Time. In addition to Drilling KPIs, Neptune also focused on Tripping, Casing, and in completion Screen, and Tubing KPIs. Successful drilling optimization lies in continuous improvement and targeted control over an extended period based on global best practices. Therefore, Neptune Energy was able to gain considerable time savings.

From the figures below, it can be seen that:

| Key Performance Indicators | Actual Savings [d] |

|---|---|

| Tripping – Slip to Slip Connection Time | 12.0 |

| Tripping – Pipe Moving Time | 4.5 |

| Drilling – Weight to Slips Time | 0.2 |

| Drilling – Slip to Slip Connection Time | 0.6 |

| Drilling – Slips to Weight Time | 0.5 |

| Casing – Slip to Slip Connection Time | 2.8 |

| Casing – Pipe Moving Time | 1.5 |

| Screen – Slip to Slip Connection Time | 0.03 |

| Screen – Pipe Moving Time | 0.1 |

| Tubing – Running Slip to Slip Connection Time | 0.3 |

| Tubing – Pipe Running Time | 0.3 |

| Summation of Actual Savings | 22.8 |