Improving and developing innovative solutions in pre-salt exploration

Using tde pronova since 2012, this mixed-capital South American company works closely with tde, a partnership with the drive to improve the efficiency and safety of drilling operations.

Executive Summary

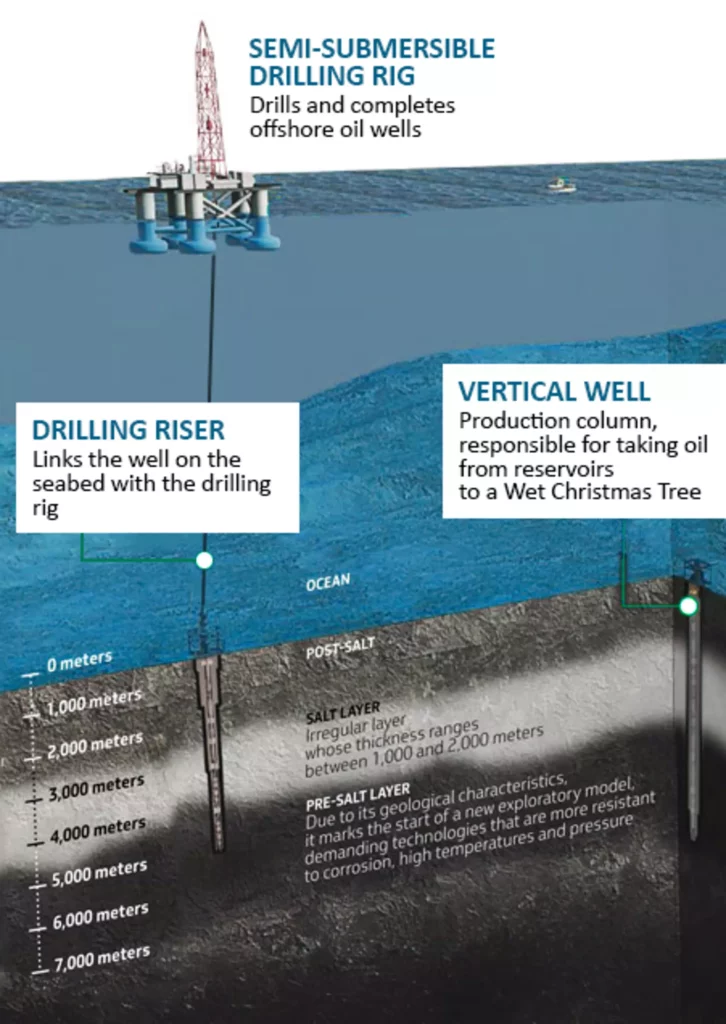

Due to the world’s oil demand and discovery of an additional reservoir type (pre-salt) in 2006, the company faced a major challenge – to drill more wells in less time through continuity and efficiency over the entire rig fleet. By incorporating proNova in 2012, the company was able to manage their well operations more efficiently. Well construction costs were lowered through shorter drilling times and in turn, those savings were dwarfed by early production revenues.

Challenges

Unexplained performance differences were experienced throughout the fleet, as there were no set standard practice guidelines. Different rig designs, drilling packages and rig equipment were being used for routine well operations. Even using the most advanced drilling rigs available, the company still faced unexplainable differences in well delivery times.

How tde pronova helped

Using tde pronova, the company was able to identify significant performance differences related to a myriad of factors. Two of the larger issues were related to the drilling package models and overtorque.

tde pronova identified a huge performance gap between the manual and automated rigs, suggesting a change in the drilling package was needed for the latter. Working closely with the contractor and using multiple KPIs to monitor the effect of individual changes, the drilling package was optimized, and the performance gap was closed. Additionally, tde pronova identified an overtorque issue after observing longer than usual tripping connection times. Remarkably, proNova narrowed the issue down to a rather unconventional problem; the pipe dope (thread grease) needed to be better adjusted for the well conditions. proNova again monitored the individual measures taken and the optimal compound was found. In the end, proNova essentially broke the paradigm that manual rigs are “faster” and more efficient than automated rigs.

tde pronova provides Key Performance Indicators (KPIs), allowing the company to analyse and optimize their contractor’s performance. Through this partnership, both a Global Performance KPI and an Executive Dashboard were created to provide a more practical performance indicator. The company was the first to use proNova to this effect. Through drilling operations analysis, lessons learned and benchmark sharing, tde pronova’s innovative and flexible drilling optimization service helps clients maintain continuous savings and revenue growth in the never-ending pursuit of maximum drilling efficiency.