Reaching Technical Excellence and Reducing ILT saves Aker BP $3.5m* (90 equivalent rig hours)

| Location | Norwegian North Sea |

| Rig | Deepsea Stavanger |

| Date | 2019-2020 |

| Country | Norway |

Challenges

Aker BP with Oddfjell Drilling set out to seek operational excellence by employing tde pronova tde to monitor and implement KPIs across three rig operations with the aim to be ‘best of the best’ during campaign lifespan.

How tde pronova helps

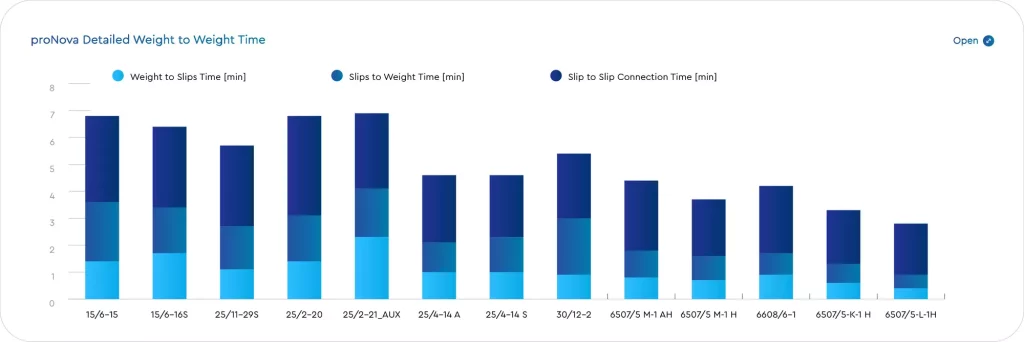

Aker BP utilized one team approach, emphasis was placed on controlling the components of Weight to Weight connection times, including Weight to Slips Time, Slip to Slip Time and Slip to Weight Time. This strategy drastically improved the rig performance resulting in several operational records being achieved over the course of campaign. By fine tuning operational procedures being monitored by proNova and making incremental changes, Aker BP were able to gain significant time savings across the drilling campaign.

Results

| Key Performance Indicatiors | Actual Savings (h) |

| Drilling – Weight to Weight Time | 17.7h |

| Tripping – Slip to Slip Connection Time | 65.4h |

| Tripping – Pipe Moving Time | 6.9h |

“Thanks for your help to enable us to achieve our efficiency goals!

Lead Drilling Engineer

The service we receive has been first class to help adapt to meet our specific needs. Aker BP and proNova have been working together to help deliver best in world class well delivery. proNova is a fantastic tool that enables us to make every minute count to identify and remove waste from the operations and help our fleet be the best of the best.”

D&W – I&P – Performance

Aker BP