We are a pioneer in innovative data driven technology and sustainable solutions with more than 24 years of experience in the energy industry.

Experience

Our specialized divisions:

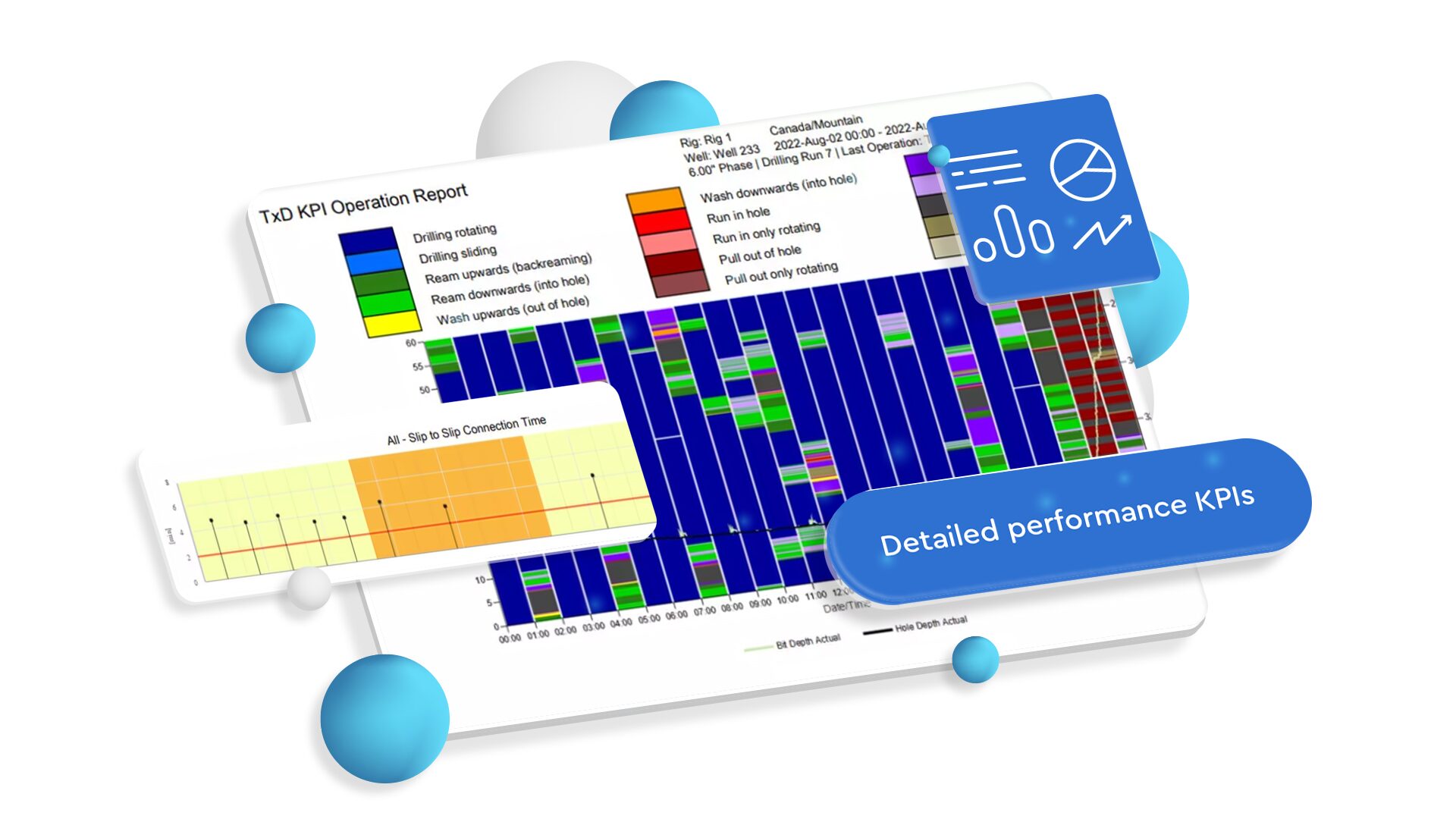

tde digital – Featured products:

Performance evaluation

tde pronova

tde pronova is a global standard and independent performance evaluation platform with proven savings and customer satisfaction while reducing environmental impact.

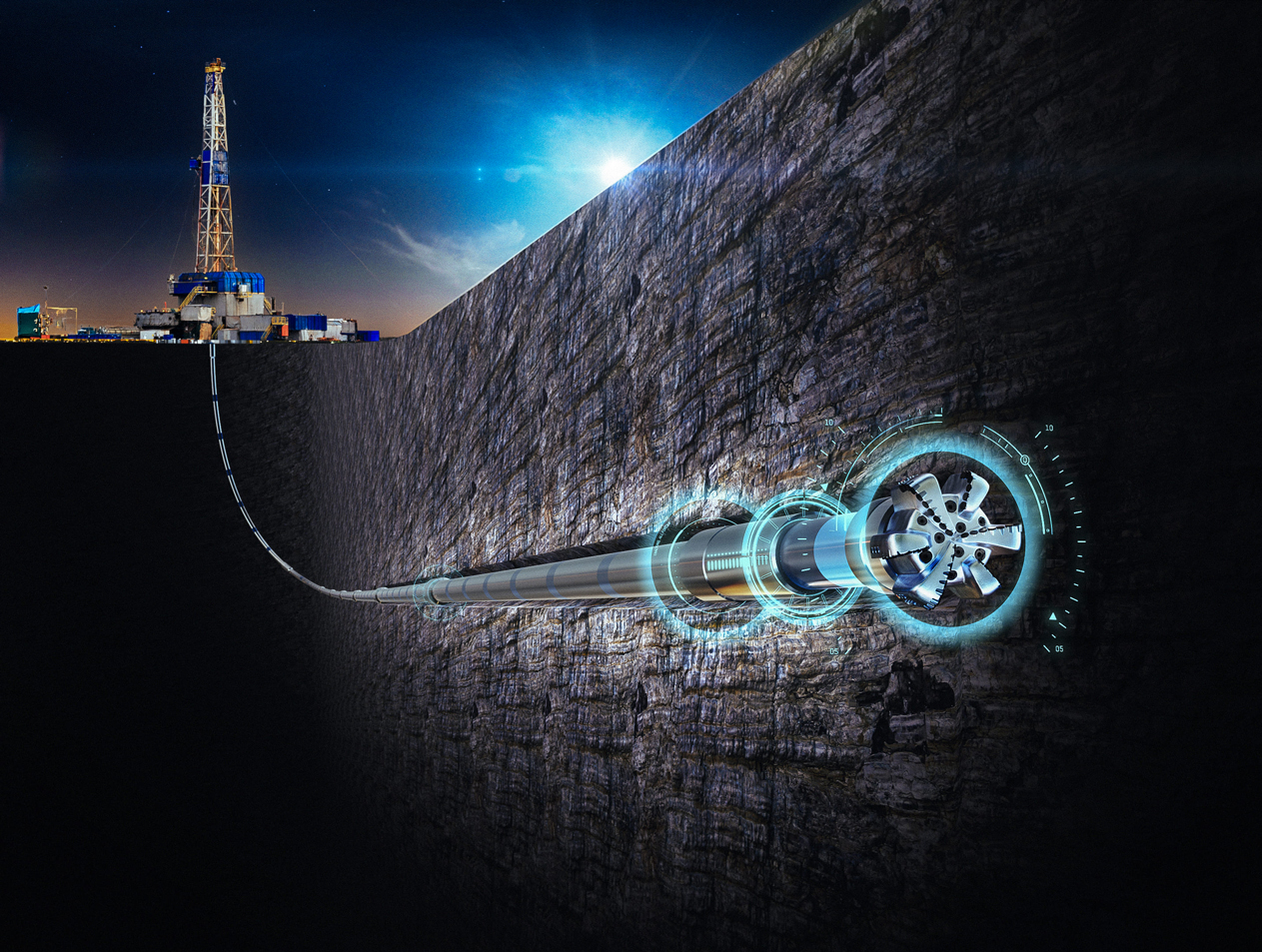

Downhole power and communication

tde powerline

tde powerline will be the industry’s first power and data highway technology, an intelligent digital drilling system, which is a key enabler for drilling automation at the edge.

Why tde?

Innovation

and Expertise

Embrace over 20 years of leading in data-driven tech and sustainability. Our global reach and local insights provide tailored strategies, keeping you ahead in the ever-changing energy sector.

Sustainable

Excellence

We’re committed to transforming the energy industry into one that’s both productive and green, underlining your commitment to a better planet.

Partner for

progress

Our partnership philosophy means your success is our success. Benefit from our track record of enhancing operational excellence and sustainability.