Automated well operations planning supported by the OSDU™ Data Platform turns historical data into time & cost savings for deep drilling

Customers in the energy industry – especially geothermal, oil and gas – are spending large sums of money for planning well construction projects. The process can take weeks to months because of heavy manual data manipulation, lack of reference data and inconsistent risk management.

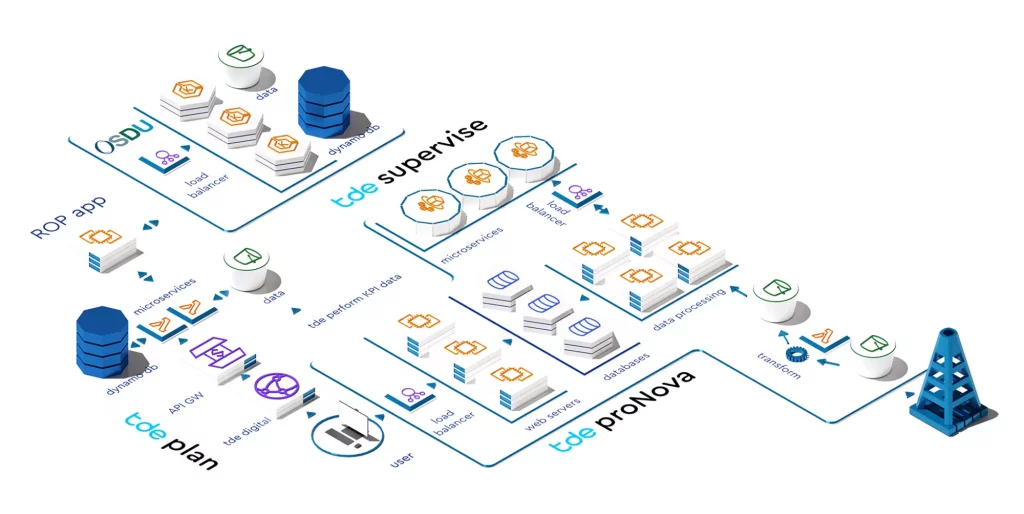

View this video on the AWS website to see our software meet these challenges by leveraging sensor data, automating workflows with AI and ML and integrating the OSDU Data Platform. tde leverages AWS technologies and the OSDU™ Data Platform to offer a new cloud-native application for modelling and optimizing automated well operations planning, with ROP being one of the most critical drivers of drilling performance where drilling organizations can save millions with small improvements.

Customers in the energy industry, especially geothermal and oil and gas, must drill several thousands of meters into the ground to get to the valuable resources. Whoever tried to drill holes in concrete walls, knows how hard this can be and thus optimizing the speed with which the rock is destroyed, and hole is made – the rate of penetration (ROP) – is a critical driver for the total expenditure of such projects.

tde has built a new software application to help companies in this sector to model and optimize ROP with the help of AI and ML. The software connects to the customer’s OSDU™ Data Platform to pull geological reference data and to store results. With the app, customers can select best performing equipment and operating parameters and store the results back into the OSDU™ Data Platform, where they are shared with other applications.

Miodrag Ivanovic, VP Tech at tde: “Our customers are increasingly adopting the OSDU™ Data Platform but still experience challenges to turn the data to value. We saw great potential in a solution that uses geological historical data available in the OSDU™ Data Platform model to predict the maximum ROP and best operating parameters for future drilling projects. With this app, we help our customers to turn their investment in data acquisition and data platforms into real value.”

tde plan, where the AI-driven ROP modelling will be available will allow customers to estimate planned well construction time based on what is possible and not to rely on past offset performance. Operators will be able to set better ROP goals for service providers and bit manufacturers and drill wells faster.

If you want to improve your ROP and create value from your OSDU™ Data Platform, then contact us.